Light Gauge Steel Framing and the Future of Commercial Construction in Florida

The commercial construction industry is constantly evolving, with new technologies and materials shaping the way buildings are designed, built, and maintained. As the demand for more sustainable, efficient, and resilient structures grows, Light Gauge Steel (LGS) framing is emerging as a key player in the future of commercial construction, particularly in Florida. In this post, we’ll explore how LGS framing is driving innovation in the industry and why it is positioned to become the go-to material for future commercial projects.

1. Sustainable Building Solutions for the Future

As environmental concerns become more pressing, the construction industry is shifting toward more sustainable building practices. Light Gauge Steel framing is at the forefront of this movement, offering developers a material that is both eco-friendly and durable.

- 100% Recyclable Material: Steel is one of the most recyclable materials available, making LGS framing a sustainable choice for developers who want to reduce waste. As environmental regulations tighten and the push for green building practices grows, the recyclability of steel will continue to be a major advantage in the industry.

- Energy Efficiency: LGS framing contributes to energy-efficient building designs by reducing thermal bridging and supporting modern insulation systems. As energy costs rise and developers look for ways to reduce carbon footprints, the energy efficiency of steel-framed buildings will play an increasingly important role.

With sustainability driving the future of construction, LGS framing is well-positioned to support eco-friendly projects that align with modern environmental goals.

2. Faster, More Efficient Construction Processes

As the demand for quicker construction timelines grows, developers are turning to Light Gauge Steel framing for its efficiency and speed. The ability to prefabricate LGS components off-site allows for faster project completion, making it ideal for the fast-paced nature of commercial construction.

- Prefabrication for Faster Builds: LGS components are manufactured in a controlled environment and arrive on-site ready for assembly. This reduces on-site labor, shortens construction timelines, and minimizes the impact of weather-related delays. In the future, more projects will lean on prefabrication to meet deadlines without sacrificing quality.

- Reduced Labor Costs: With fewer workers needed for assembly and less time spent on framing, LGS framing offers cost savings that will be increasingly important as labor shortages and rising wages challenge the construction industry.

The future of commercial construction will be defined by speed and efficiency, and LGS framing provides a solution that meets these demands.

3. Resilience Against Climate Challenges

Florida’s commercial construction market faces unique challenges due to the state’s vulnerability to hurricanes, high humidity, and rising sea levels. Light Gauge Steel framing provides a material that can withstand these environmental stressors, ensuring that buildings remain resilient in the face of climate change.

- Hurricane Resistance: LGS framing is strong enough to withstand high winds and heavy rain, making it an ideal choice for buildings in hurricane-prone areas. As the frequency and intensity of storms increase, the demand for hurricane-resistant materials will continue to rise.

- Moisture and Corrosion Resistance: Steel is impervious to moisture and corrosion, making it a better choice than traditional wood framing in Florida’s humid climate. With more developers focusing on long-term resilience, LGS framing offers a durable solution that protects against environmental damage.

As climate change reshapes the construction landscape, LGS framing will play a key role in helping developers build more resilient commercial properties.

4. Technological Innovation and Smart Building Design

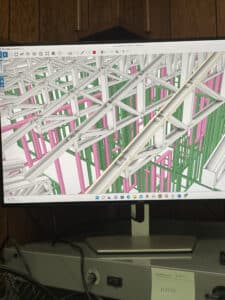

The future of commercial construction is increasingly intertwined with technology, and Light Gauge Steel framing is at the center of this shift. As developers and architects embrace new technologies like Building Information Modeling (BIM) and smart building systems, LGS framing provides the flexibility and precision needed to integrate these innovations.

- BIM Compatibility: LGS framing works seamlessly with BIM, allowing for precise, digital modeling of the entire building process. This ensures greater accuracy in design, reduces errors during construction, and improves collaboration among architects, engineers, and builders. As BIM becomes standard in commercial construction, LGS framing will be a natural fit for projects that require high levels of precision.

- Smart Building Integration: LGS framing supports the integration of smart building systems, including energy management, automated lighting, and environmental monitoring. As commercial buildings become smarter and more connected, LGS framing’s versatility and strength make it an ideal material for housing advanced systems.

By embracing technological innovations, LGS framing is helping developers design the commercial buildings of the future, where sustainability, technology, and performance are seamlessly integrated.

5. Adaptability to Changing Commercial Needs

As the commercial real estate landscape evolves, buildings must be designed to accommodate changing tenant needs, business operations, and market trends. Light Gauge Steel framing offers the flexibility needed to create adaptable commercial spaces that can evolve over time.

- Open Floor Plans for Flexibility: LGS framing allows for open, column-free spaces that can be easily reconfigured to meet the changing needs of tenants. As more businesses seek flexible office spaces, retail environments, or mixed-use developments, the adaptability of steel framing will become a key asset in the commercial construction market.

- Support for Multi-Use Developments: The rise of multi-use developments—combining residential, commercial, and recreational spaces in one building—requires materials that can support diverse functions. LGS framing’s versatility and strength make it ideal for these types of projects, where flexibility is essential for accommodating different uses.

In a commercial real estate market that increasingly values flexibility and adaptability, LGS framing provides a future-proof solution that can accommodate shifting demands.

6. Long-Term Cost Savings Through Durability

As developers and building owners look to reduce long-term operational costs, the durability and low maintenance requirements of Light Gauge Steel framing will continue to drive its popularity in commercial construction.

- Low Maintenance Requirements: Steel’s resistance to pests, moisture, and fire means that LGS-framed buildings require far less maintenance than structures built with wood or other traditional materials. This reduces long-term costs for building owners, making steel-framed buildings more cost-effective over time.

- Longevity and Durability: LGS framing ensures that commercial buildings remain structurally sound for decades, reducing the need for costly repairs or replacements. As developers focus more on long-term value, the durability of steel will become a critical factor in their decision-making.

By offering both short-term construction efficiencies and long-term savings, LGS framing provides a cost-effective solution that benefits both developers and building owners.

Conclusion: The Future of Commercial Construction with LGS Framing

As the commercial construction industry continues to evolve, Light Gauge Steel framing is emerging as a key material for meeting the demands of the future. With its sustainability, resilience, adaptability, and compatibility with modern construction technologies, LGS framing offers a solution that addresses the challenges of today while preparing for the needs of tomorrow. For developers looking to stay ahead of the curve, LGS framing is the material of choice for future-forward commercial projects in Florida and beyond.

Contact Elite Steel Today! Ready to future-proof your next commercial project with Light Gauge Steel framing? Contact Elite Steel at 1-904-799-6499 or visit elitesteel.com to learn how LGS framing can help you build for the future of commercial construction.

SEO Keywords: